what is cobbing of iron ore processing

The six main steps of iron ore processing - Multotec

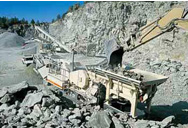

Six steps to process iron ore 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing. This step prevents

Charlar en Línea

Iron Ore Processing - an overview ScienceDirect Topics

This review focussed on two main aspects of oolitic iron ore processing: beneficiation by conventional mineral processing techniques (differential grinding, scrubbing, gravity

Charlar en Línea

Iron Ore Processing, General SpringerLink

2022.10.20 Making iron and steel from iron ore requires a long process of mining, crushing, separating, concentrating, mixing, agglomeration (sintering and pelletizing),

Charlar en Línea

Life cycle assessment of iron ore mining and processing

2015.1.1 Mining of iron ore is a highly capital- and energy-intensive process. Life cycle assessment (LCA) of the mining and mineral processing of iron ore in Australia

Charlar en Línea

The Chinese Iron Ore Deposits and Ore Production

2018.7.11 China’s imports of iron ore are mainly iron ore powder, massive iron ore (raw ore) and pellets, respectively, from more than 30 countries and regions, in which Australia, Brazil, India and South Africa

Charlar en Línea

Iron Ore Characterization Techniques in Mineral Processing

2023.4.27 While iron is a pivotal metal that is exploited commercially, its extraction from ores, subsequent process- ing and purification follows a series of steps, and

Charlar en Línea

Iron processing - Ores, Smelting, Refining Britannica

The most widely distributed iron-bearing minerals are oxides, and iron ores consist mainly of hematite (Fe 2 O 3), which is red; magnetite (Fe 3 O 4), which is black; limonite or bog

Charlar en Línea

Iron Ore Sintering: Process: Mineral Processing and

2017.3.24 Sintering is a thermal agglomeration process that is applied to a mixture of iron ore fines, recycled ironmaking products, fluxes, slag-forming agents, and solid fuel (coke). The purpose of the sintering

Charlar en Línea

Copper extraction - Wikipedia

The Chino open-pit copper mine in New Mexico Chalcopyrite specimen from Huarón mine, Peru. Copper extraction refers to the methods used to obtain copper from its ores.The conversion of copper ores consists of a series of physical, chemical and electrochemical processes. Methods have evolved and vary with country depending on the ore source,

Charlar en Línea

Iron ore BHP

Iron ores are rocks and minerals from which metallic iron can be extracted. There are four main types of iron ore deposit: massive hematite, which is the most commonly mined, magnetite, titanomagnetite, and pisolitic ironstone. These ores vary in colour from dark grey, through to deep purple, rusty red and bright yellow.

Charlar en Línea

Case Study of Dry HPGR Grinding and Classification

2019.2.5 Frank Meer. Dry HPGR processing is gathering interest from industries that are operating in areas where water scarcity or process conditions do require a minimizing of water addition and ...

Charlar en Línea

Iron Ore Processing,Crushing,Grinding Plant Machine

Iron ore is the key raw material for steel production enterprises. Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization. After crushing, grinding, magnetic separation, flotation, and gravity separation, etc., iron is gradually selected from the natural iron ore.

Charlar en Línea

Intensity Magnetic Separation - an overview - ScienceDirect

Example of magnetic pulley used to remove tramp iron from an ore prior to further processing (Courtesy Eriez). Dry low-intensity magnetic separation is confined mainly to the concentration of coarse sands which are strongly magnetic, a process known as “cobbing,” and is often carried out using drum separators.

Charlar en Línea

Mineral processing - Wikipedia

Mineral processing can involve four general types of unit operation: 1) Comminution – particle size reduction; 2) Sizing – separation of particle sizes by screening or classification; 3) Concentration by taking advantage of physical and surface chemical properties; and 4) Dewatering – solid/liquid separation. In all of these processes ...

Charlar en Línea

Low grade Iron Ore Beneficiation and the Process of Jigging

2018.9.25 Since the iron ores consist of several compositions, mineralogies, shapes, and sizes, so there is no ‘one size fits all’ approach to the beneficiation of iron ore. Most of the ‘run-of-mine’ (ROM) iron ore contain a large percentage of other materials which need to be removed through the process of beneficiation before the ore attains the

Charlar en Línea

Iron Ore - an overview ScienceDirect Topics

Iron ore is regarded as the second most important commodity behind oil. As an essential input for the production of crude steel, iron ore feeds the world’s largest trillion-dollar-a-year metal market and is the backbone of global infrastructure. To meet the growing demand for steel products, world iron ore production has increased ...

Charlar en Línea

Introduction: Overview of the global iron ore industry

2022.1.1 Abstract. Iron ore is regarded as the second most important commodity behind oil. As an essential input for the production of crude steel, iron ore feeds the world’s largest trillion-dollar-a-year metal market and is the backbone of global infrastructure. To meet the growing demand for steel products, world iron ore production has increased ...

Charlar en Línea

allmineral – alljig® – reliable and sustainable allmineral ...

Ore mining with alljig® In the south-east of Australia, alljig ® jigs boasting low energy and investment costs are hard at work processing iron ore. This innovative system, which was adapted to suit the new conditions at the Iron Baron Mine, represents a major triumph for allmineral and SIMEC Mining alike.

Charlar en Línea

Basics of mineral processing PPT - SlideShare

2017.7.28 8. 8 Size reduction of ores is normally done in order to liberate the value minerals from the host rock. it is done through Crushing and grinding of ore and minerals. this is also called as liberation the

Charlar en Línea

Iron - PUB2895 Missouri Department of Natural Resources

2020.10.7 Commodity Iron is a brittle, steel gray to silvery gray metal used through millennia. Advent of its use was so significant that the Iron Age of human prehistory is named for the dominant use of the metal. Iron has had numerous names throughout human history. Our current name for the metal is likely from Middle English and was itself

Charlar en Línea

Wet low intensity magnetic separators

Iron ore processing General Metso has produced several thousand Low In-tensity magnetic separators (LIMS) ... Iron ore separation 8 000 – (15 000) ... 100 – 160 200 – 350 Concurrent Coarse (Cobbing) 0 – 10% Counter-rotation Iron ore separation 2 000 – 5 000 80 – 120 200 – 350 Counter-rotation

Charlar en Línea

The Step-by-Step Process of Producing Iron from Iron Ore

2017.10.23 The raw materials mix or “charge” enters the furnace from the top and hot air is blown or blasted from the bottom causing the coke to burn and the oxygen to combine with carbon in the coke to form carbon monoxide. Now, this carbon monoxide that is unstable, reacts with the ore to form carbon dioxide and iron. The Separation Of Iron-.

Charlar en Línea

Iron processing - Smelting, Refining, Alloying Britannica

Iron processing - Smelting, Refining, Alloying: The primary objective of iron making is to release iron from chemical combination with oxygen, and, since the blast furnace is much the most efficient process, it receives the most attention here. Alternative methods known as direct reduction are used in over a score of countries, but less than 5 percent of iron is

Charlar en Línea

Iron Ore - an overview ScienceDirect Topics

Mineral Sampling. A. Gupta, D.S. Yan, in Mineral Processing Design and Operation, 2006 1.1. Iron ore was sampled before stock piling with a stacker. One hundred samples taken from the stacker-conveyor showed a standard deviation in the iron assay of ± 0.5 %. The ore assayed, on average, 59 % Fe.Sieve analysis of the samples showed that the largest

Charlar en Línea

Different Types of Iron Ore - 911 Metallurgist

2016.10.5 Different Types of Iron Ore. The iron minerals that are at present used as ores are hematite, magnetite, limonite, and siderite; also, occasionally ankerite, goethite, and turgite. Hematite is the most important iron ore. The iron content of the pure minerals is as follows: Ankerite is a carbonate of lime, magnesia, manganese, and iron.

Charlar en Línea

Life cycle assessment of iron ore mining and processing

2015.1.1 Abstract. Mining of iron ore is a highly capital- and energy-intensive process. Life cycle assessment (LCA) of the mining and mineral processing of iron ore in Australia was carried out in this chapter using SimaPro LCA software as a case study. The environmental impacts considered in the study were embodied energy and greenhouse

Charlar en Línea

Current Status of Copper-Ore Processing: A Review

2021.9.8 In recent times, a low copper content in ores has been observed (ores containing 0.2–0.3% copper are used for processing in Canada and the United States, and ores containing at least 0.4% copper are used in Russia []) owing to the exhaustion of rich copper resources.The flowsheet of processing copper ores is developed for each

Charlar en Línea

Iron Ore, Types, Uses, Distribution in India World Map

2023.6.28 Iron Ore Types. They are classified according to the percentage of metallic iron in them: Magnetite: It is the most valuable type of iron ore. It is made up of more than 70% metallic iron. It is black and has magnetic properties. Hematite: It is composed of 65-70 per cent metallic iron.

Charlar en Línea

>> Next:Moledoras De Cereales Industriales

- productores trituradora de impacto santiago

- dise&241;o de catálogo de planta de trituración

- bandas transportadoras proporciona

- molinos de bola mexico

- sistema de medicion de carga de un molino bolas

- trituradora de mandíbula 150000 jam ton

- molino vertical de ahorro de la tierra

- Mecanismo De Trituradora De Piedra Para El Proyecto Mecanico

- molino de bolas cementero tama o de la bola

- maquinarias o equipos para mineria de oro

- especificaciónes tecnicas de trituradoras

- Trituradora en Los Guaicas

- bajo consumo molino de bolas parrilla

- coal exploitation industry in south africa

- méxico mineral de hierro para la venta