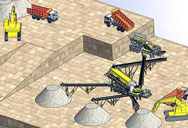

Screens And Crusher For Mining Industry

Crushing and Screening Handbook - AusIMM

dwheeler, Omnibelt, Omnicone, Omnimatic, Orion, Pyrotherm, Reed, Sala, Scanmec, Screen-All, Seco, Senator, Simplicity (slurry pumps), Skega, Stansteel, Stephens

Charlar en Línea

Crushers and screens recommender - Metso

Choose your requirements for crushers and screens, and we will help you to compare and choose the right machines for your aggregate production. Compare and choose crushing and screening machines for your

Charlar en Línea

SANDVIK SG SG-H GRIZZLY SCREENS - Sandvik Mining and

2020.4.30 separation. SG screens are often combined with a reciprocating plate feeder when heavy dump loads and high capacity is required, in conjunction with a by-pass of the fines ahead of the crusher. SG screens (excluding SG2452X) have their vibrating mechanism mounted under the feeder body as standard. The double shaft mechanism

Charlar en Línea

Crushers, breakers and grinding mills for the mining industry

Selecting the correct crusher depends on ore characteristics such as abrasiveness, fragility, softness or stickiness, and the desired outcome. The crushing process can include primary, secondary, tertiary and even quaternary crushing stages. Screens are used to separate rocks, ores and other materials by size.

Charlar en Línea

Mining Crushers AllMinings

2023.12.5 A mining crusher is a machine used to reduce large rocks into smaller pieces. Crushers are designed to handle a range of materials. It is from ores to coal and various minerals used in the mining industry. There are several types of crushers commonly used in mining operations: Jaw Crusher. Gyratory Crusher.

Charlar en Línea

Crushing and Screening Handbook - AusIMM

TABLE OF CONTENTS Chapter Subject / section name Preface Table of Contents Metso’s Mining and Construction Technology 1 Quarry Process + Process Integration and Optimization (PIO) 2 Feeders 3 Crushing Equipment 3 C-Series Jaw Crushers 3 Superior MK-II Primary Gyratory Crushers 3 GP Series Cone Crushers 3 MP Series Cone

Charlar en Línea

VG Series™ scalping screens - Metso

The long stroke capability enables better scalping efficiency, delivering a linear motion with high G force (5.5 G). VG Series™ scalping screens are slightly inclined at 5° to reduce blinding when feed is sticky and contains fines (increased capacity). They can be fitted with various grizzly bar options to allow wide separation flexibility.

Charlar en Línea

Determination of semi-mobile in-pit crushing and conveying

2021.2.12 In-pit crushing and conveying (IPCC) systems are currently receiving more attention as a result of the existing characteristics of open-pit mining operations and what is likely to happen in the future. The use of trucks and shovels for loading and hauling has been used as a dominant system in open-pit and open-cast mines due to their large

Charlar en Línea

Mobile crushers and screens - SRP

Mobile crushers and Screens. We offer a wide range of mobile crushers and screens, both tracked and wheeled, to help you process rock in the toughest conditions. This selection includes jaw crushers, impactors, cone crushers, screens and scalpers for quarrying, construction and rock excavation projects.

Charlar en Línea

Crushing Screening Plant - 911 Metallurgist

2016.7.12 These screens are closed-circuited with a 5½-ft. Symons short-head crusher, and the undersize is passed to a bank of six 4- by 6-ft. Hummer screens having 3/16- by 5/8-in. openings. The oversize passes to the fourth stage of crushing—Traylor 78- by 18-in. rolls , the product of which is returned to the screens, while the undersize

Charlar en Línea

Long-lasting roller crusher and sizer solutions I FLSmidth

Robust roller crusher and sizer offering to maximise your crushing capabilities. Our roller crushers and sizers are built to last, with strong frames and self-lubrication systems to reduce your maintenance burdens. They offer reliable crushing of materials in the cement and mining industry, including highly-abrasive and sticky ones, and ...

Charlar en Línea

The Complete Guide to Primary Crushing, Secondary Crushing,

2023.2.28 Roll crushers are used for producing finer product sizes and are often used in the mining industry. Working Principle of Secondary Crushers The working principle of secondary crushers varies depending on the type of crusher, but generally, they work by applying pressure to the material through compression or impact.

Charlar en Línea

Crushing and sizing technology for all stages - FLSmidth

Crushing and sizing equipment that’s up to the task. The demands on your crushing and sizing equipment are extreme. Crunching up rock without breaking teeth. Reducing sticky and soft materials without clogging. Your process depends on the ability of these machines to do their jobs – so we make it our job to provide crushing and sizing ...

Charlar en Línea

Lokotrack® - mobile crushers and screens - Metso

Mobile crushers and screens. Originally developed and manufactured by Metso since 1985, Lokotrack® mobile crushing and screening plants are widely used in aggregates production and recycling applications around

Charlar en Línea

Screening Plants — Types, Working Principle Applications

2018.3.1 Inclined screens are commonly used for crushing rocks, sand , and gravel; recycling; ore processing; wet screening and for the chemical industry. Rotary screens: A common usage of rotary screens ...

Charlar en Línea

Portable Crushing Screening Plants Minyu Machinery Corp.

2023.8.7 Minyu's plants are perfectly suited for the mining industry, construction, water conservancy, metallurgy, ... Crusher Screen/Feeder Motor Power Rating (kw) Throughput (TPH) Total Unit Weight (kg) MSCM2416: MS2416 / MCC600: MVG924 / MOP1542T: 108: 40-60: 33,000: MSM2416: MS2416: MVGH824: 64:

Charlar en Línea

Gold Mining Rock Crushers and Crushing Plants: A Complete Guide

2023.2.22 Using quality rock crushers in your gold mining operation can bring a range of benefits, including increased efficiency and reduced operating costs. By investing in quality equipment, you can: Increase your production rate and throughput. Reduce your maintenance costs. Improve the quality of your final product.

Charlar en Línea

Product Center

Our products cover crusher, grinding mill, screen ... (large circular vibrating screen standard), JB/T12811-2016 (hydraulic high frequency screen), etc. Nearly ten national industry standards. The product ... vertical shaft crushers, vibrating screen, etc. have been widely used in the mining and aggregates industry MP series mobile ...

Charlar en Línea

Industrial Crushers - Double Roll Crusher Manufacturer from

Star trace roll crusher can be referred to as compression-type roll crusher. in the mining industry, they are used to crush mines of medium or low hardness, rocks that have low or medium rigidity during mine selection, for cement, chemicals, and industrial production of building materials, among others. roll crushers have the advantage of producing a close

Charlar en Línea

Everything you need to know about screening - Metso

2021.9.30 In aggregate production, the screening process is a key part of the production process and is carried out on a large scale. Therefore, it is necessary to make sure that the screening is done in the right way, ensuring greater productivity and efficiency. Metso Outotec has created a quick guide so that you would know the subject better and

Charlar en Línea

Five steps to optimize crusher’s lubrication system - Metso

2018.7.30 At minimum, lube system maintenance checks, inspections or servicing must include the following steps: 1. Monitoring of lube oil temperature. A lot can be learned about a cone crusher by simply watching the supply oil temperature and comparing it to the return oil temperature. Return oil temperature should be in the range of 60~140ºF

Charlar en Línea

Crushing Screening Equipment Australia Quarrying Mining

The VS350 is a skid mounted vertical shaft impact crusher for use in tertiary and quaternary crushing applications. It is a versatile crusher primarily used for producing sand and fines and quality enhancement of aggregates. Maximum Feed Size. Up to 120mm (Dependant on rotor option) Rotor Diameter. 1000mm.

Charlar en Línea

- precarga de balineras de un reductor de una trituradora de piedra

- aceites esenciales los molinos

- pulverising and screening of kaolin

- trituradora de piedra con motor diesel

- subsidio para la molienda de minerales

- trituradora móvil de 150 toneladas de capacidad de carbón ruso

- precio de trituradora de piedra valentini

- triturador de solidos en electroluz

- filipinas molino de mineral de oro

- principales yacimientos minerales colombia

- paint industry ultrafine grinding

- trituradora casera

- ashok piedra trituradoras de china

- cono cotización trituradora

- Trituradora de piedra Jatim