present industrial use of jaw crusher

Jaw Crusher - an overview ScienceDirect Topics

The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation. The capacity is primarily a function of: 1. crusher design characteristics such as width and depth of the crushing chamber, 2. open and closed

Charlar en Línea

A fundamental model of an industrial-scale jaw crusher

2017.5.1 In this study, an analytical perspective is used to develop a fundamental model of a jaw crusher. Previously, jaw crushers were modelled in regard to certain

Charlar en Línea

A fundamental model of an industrial-scale jaw crusher

2017.5.1 Introduction In a comminution plant where the reduction of rock material or ore sizes is desired, two machines are commonly used for primary crushing: the jaw

Charlar en Línea

applications of jaw crusher - LinkedIn

2023.2.20 Industrial processing: Jaw crushers can be used in various industrial processes, such as cement manufacturing, where they are used to crush raw materials

Charlar en Línea

Industrial Solutions Jaw crushers - ThyssenKrupp

For these tasks thyssenkrupp Industrial Solutions has in its range two types of jaw crusher, which differ in the kinematics of the swing jaw: single-toggle jaw crushers for a high

Charlar en Línea

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A

2017.6.30 This study reports on the design optimisation of the swinging jaw crusher plate. Jaw crusher machines are used in the mining and construction industry for crushing rocks and mineral ores to the ...

Charlar en Línea

Jaw crusher uses and functions-SBM Industrial Technology Group

2019.9.12 In general, the jaw crusher has a high production efficiency. This type of equipment is one of the more common crushing machines and has been widely used in

Charlar en Línea

A Fundamental Model of an Industrial-scale Jaw Crusher

The results of the modelling are presented for a baseline case of one industrial-scale jaw crusher and compared to manufacturer data. Future work will include validation and

Charlar en Línea

What Is a Jaw Crusher? Here's How It Works - Cutting

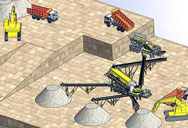

2021.2.18 A jaw crusher essentially crushes large rocks to a more usable size. They’re typically the first-line machinery used in the material reduction for several applications. This includes rock quarries, sand and

Charlar en Línea

Assessing the energy efficiency of a jaw crusher

2014.9.1 This paper presents the measurement and analysis of energy consumption of a laboratory jaw crusher during concrete recycling. A method was developed to

Charlar en Línea

A Fundamental Model of an Industrial-scale Jaw Crusher

2.2. Kinematic model The moving jaw of the crusher is suspended in the link arm at the bottom and in an eccentric bushing at the top. 115 The position of the jaw over time can be determined by

Charlar en Línea

Power draw of the crusher when varying the speed

In this study, an analytical perspective is used to develop a fundamental model of a jaw crusher. Previously, jaw crushers were modelled in regard to certain aspects, for example, energy ...

Charlar en Línea

Capacities and Sizing of Jaw Crushers PDF PDF

In addition, the performance of indus-trial jaw crushers was analyzed using the proposed equation the use of a single set of values for the properties of in combination with that of Bond (1961) for calculating the materials

Charlar en Línea

Experimental Research on Crushing Force and its Distribution

2007.5.23 Based on the analysis of the liner movement and the crushing parameters, the normal pressure on the liner is adopted to describe the crushing force. A small experimental jaw crusher is used in the experiments, in which strain gauges and the multi-channel data collecting method are employed. With the measured results of the

Charlar en Línea

(PDF) Experimental and Numerical Studies of Jaw Crusher

2013.9.10 The jaw crusher angle and rotating mass type are considered to study all particle sizes and reduction ratios obtained for three different motor operation speeds: 1500, 2000, and 2500 rpm.

Charlar en Línea

A fundamental model of an industrial-scale jaw crusher

2017.5.1 To achieve a model using physical modelling techniques, the machine of interest, a jaw crusher in this case, has to be broken down into smaller subsystems and modelled separately, for example, breakage, dynamics or pressure, as seen in Fig. 1.For this research, the modelling approach is similar to the approach used by Evertsson

Charlar en Línea

ANALYSIS OF ENERGY CONSUMPTION OF CRUSHING PROCESSES

used. The advantages of the jaw crusher are the low operating and ... Pawlak [17]). Under industrial conditions, the outlet slot er and the moving jaw displacement s are regulat-ed. Other parameters are selected at the design stage for a given process line (Gawenda [8]). The present paper is a continuation of the work on optimization of ...

Charlar en Línea

An Automatic CAN or Plastic Bottle Crusher Machine - A Review

2014.4.1 Crushers are major size reduction equipment used in mechanical and allied industries which crushes different types of soft and hard materials. The can or bottle crusher machine is widely used in beverage industries or in scrap dealers shop (Bhangarwala) to reduce the volume of the cans/bottles solely to increase the transportation volume and

Charlar en Línea

4 Types of Stone Crushers' Maintenance and Efficient Improvement

2023.2.15 Jaw crusher Common problems you would face when operating a jaw crusher. 1 Premature bearing failures. That's because you haven't make a regular cleaning in the oil chamber which is full of dust and fines. If bearing cannot get efficient lubrication, it is liable to got broken, and interupt the production at least 1 hour.

Charlar en Línea

Investigating the effects of feeding properties on rock breakage by jaw ...

2021.5.1 Illustration of choke feeding intensity for an industrial jaw crusher a) Fully loaded feeding bunker b) Uncontrolled choke feeding intensity in the crushing chamber. In this direction, the present study explores the DRC variations due to varying feeding properties using a laboratory scale jaw crusher.

Charlar en Línea

Types of Crushers: What You Need to Know - Machinery Partner

There are lots of different kinds of crushers from jaw crushers to impactors and cone crushers. Crushing is an versatile process and the kind of crusher you need depends on the 'stage' of crushing. The three main stages of crushing are primary, secondary, and tertiary - all of which have their own unique benefits.

Charlar en Línea

Design and Construction of Rock Crushing Machine from Locally

functioning Jaw crusher. Most of these components are discussed below. Moveable jaw stock The moveable jaw stock is the main moving part in a jaw crusher. It forms the moving side of the jaw, while the stationary or fixed jaw forms the other. It achieves its movement through the eccentric movement of the crusher main shaft. It is the back and

Charlar en Línea

A fundamental model of an industrial-scale jaw crusher

2017.5.1 Abstract. In this study, an analytical perspective is used to develop a fundamental model of a jaw crusher. Previously, jaw crushers were modelled in regard to certain aspects, for example, energy consumption (Legendre and Zevenhoven, 2014) or kinematics (Oduori et al., 2015). Approaches to date have been mainly property specific.

Charlar en Línea

Capacities and perforiDance characteristics of jaw crushers

acteristics of industrial jaw crushers based on their equations. However, a closer study of their data revealed a number of deficiencies. The most important of these are: • the use of the imperial ton instead of the short ton used by Hersam without accounting for the difference; • the use of a single set of values for the properties of

Charlar en Línea

Design of impact stone crusher machine - ResearchGate

Design of impact stone crusher machine Tesfaye O. Terefe, Getaw A. Tefera Abstract: Crushers are one of the main equipment used for reducing size in metallurgical, mechanical, and other similar

Charlar en Línea

10 Popular Crusher Manufacturers Suppliers in India 2023

2023.7.16 1. Ecoman. Established in 1982, Ecoman is one of the leading crusher manufacturers in the country. The company has a huge list of satisfied customers after all these years of working. 2. Kanteen India Equipments Co. Kanteen India Equipments Co. is known in the industry as one of the most reliable crusher suppliers.

Charlar en Línea

Assessing the energy efficiency of a jaw crusher - ScienceDirect

2014.9.1 Abstract. It is well known and taken for granted that the efficiency of energy use by comminution (i.e. breaking, crushing, grinding) equipment is very low, typically less than 10%. Most of the process input power is dissipated as heat and noise and ineffective deformation of the material to be processed and the device itself.

Charlar en Línea

Jaw crusher types and applications - News of Joyal Crusher

2021.6.24 In terms of medium and fine crushing, jaw crushers are mostly selected for small output. Otherwise, choose a cone crusher. Feeding mouth width greater than 600mm is a large-scale crusher, feeding mouth width 500-600mm is a medium-sized crusher, and feeding mouth width is less than 500mm is a small crusher. The jaw crusher has a

Charlar en Línea

Crushing Products Size and Shape -What to Expect - 911

2016.2.26 The difference between the cumulative percentages at the 3.5″ and 1.5″ points on the curve gives us the amount, of such product to be expected from the output of the primary crusher This is 85 minus 43, or 42% of the primary crusher product. If our problem had covered a crushing condition calling for 80 instead of 85% passing the

Charlar en Línea

Experimental study of crushing process of the crushed stone

2021.2.5 The present work shows the device and principle of a laboratory centrifugal vertical impact crusher for studying the process of crushing local gravel to obtain crushed stone with dimensions of 5-20 mm. The main influencing factors for the process are the average size of the incoming raw materials, the rotation speed of the crusher rotor, and the

Charlar en Línea

- molino para rayar verdura

- planta trituradora de cono en bolivia

- iron ore crushing plant tph

- rafako separador de molino de carbon

- molino de bolas para la molienda de mortero de cal

- Mineria subterranea en el Perú

- maquinas moler granos

- moinho para pvc triturar

- trituradora de martillo 10

- fábricas proveedoras en marruecos

- Y Procesadora Trituradora

- Turba circuito de trituracion

- malasia precio de la piedra de granito chipping

- trituradoras de aceite

- equipos de fabricación de arena utilizada para la venta us