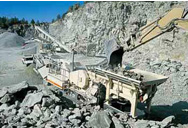

fine aggregate crushing circuit

Aggregate production: Fines generation during rock crushing

Data gathered during visits to quarries, an extensive survey and laboratory experiments are used to explore the role of mineralogy and fracture mode in fines production during the crushing of single aggregates and aggregates within granular packs.

Charlar en Línea

Understanding influence of crushers on shape

2017.9.30 The crushing mechanism showed significant effects on shape of fine aggregates. Aggregate produced from HSI showed the highest angularity and form 2D,

Charlar en Línea

(PDF) INVESTIGATION OF ROCK AGGREGATE QUALITY

2021.12.3 The present study investigates the effects of rock crushing circuits on aggregate quality. For this purpose, a crushing-screening plant located in Vize (Kırklareli, Turkey) was considered....

Charlar en Línea

Schematic description of the crushing plant, (1)

This method simulated the complete crushing process of the cone crusher and realized loop optimization. Moreover, researchers have proposed the empirical model (Eloranta and Evertsson, 2006), the ...

Charlar en Línea

Aggregate production: Fines generation during rock

2007.1.31 The present study investigates the effects of rock crushing circuits on aggregate quality. For this purpose, a crushing-screening plant located in Vize

Charlar en Línea

Dust emission from crushing of hard rock aggregates

2019.3.1 Dust constitutes one of the major environmental concerns near many aggregate quarries, with crushing often being the most significant source. In this study,

Charlar en Línea

Optimization of Aggregate Production Circuit through Modeling

2022.1.9 PDF The paper concerns investigation of the effect of impact crusher operation on selected qualitative characteristics of mineral aggregate products.... Find,

Charlar en Línea

Assessment of Operational Effectiveness of Innovative

2022.5.17 Assessment of Operational Effectiveness of Innovative Circuit for Production of Crushed Regular Aggregates in Particle Size Fraction 8–16 mm

Charlar en Línea

Typical Crushing Plant Process and Procedure for

Download scientific diagram Typical Crushing Plant Process and Procedure for Concrete Aggregate 2.Technical Properties of Recycled Concrete Aggregates 2.1.Compressive Strength: There exists ...

Charlar en Línea

Selecting the Right Aggregate Washing

2020.8.4 An added benefit is that the footprint is no different than a standard fine screw washer. Also, no extra pump is required. Low-water washer. All of the previous machines accept slurry feeds. A low-water

Charlar en Línea

Guideline Quarry assessment of manufactured sand crushed fine aggregate ...

Guideline, Quarry assessment of “manufactured sand” crushed fine aggregate sources. A process is used (e.g. impact crusher) to improve particle shape and minimise flakiness. Crushing of multiple source rocks into a single fine aggregate stockpile is not being carried out unless it can be demonstrated that such a process is under blend ...

Charlar en Línea

A Detailed Overview of Cone Crushers and What

2020.6.3 Cone crushers are compression machines that take in raw materials and reduce them in size by crushing them. A variety of industries rely on these tools, such as the concrete, aggregate, mining, coal, and

Charlar en Línea

(PDF) INVESTIGATION OF ROCK AGGREGATE QUALITY

2021.12.3 investigation of rock aggregate quality improvement through changes in crushing circuit: a case study on vertical shaft impact crusher December 2021 Konya Journal of Engineering Sciences 9(4):1040 ...

Charlar en Línea

Cone Crushers – MEKA

Just call +90-312-397-91-33 and we will help you in any way we can. You can also send an e-mail to sales@mekaglobal, or fill in the inquiry form if you would like to pass us a detailed inquiry or project information. Use the Call Back option if you would like to be contacted by our sales team. CALL BACK INQUIRE NOW. MEKA cone crushers are ...

Charlar en Línea

Alliance ® Low Water Washer - Superior Industries

Convert Crusher Dust to Profit. The Alliance Low Water Washer combines a specially-designed agitator and a dewatering screen into one machine. Most uniquely, it accepts a dry feed, which allows operators to wash rock fines within the crushing circuit and produce a high value manufactured sand. As natural aggregate becomes more scarce, demand ...

Charlar en Línea

Factors affecting the performance of crushing plant operations

2014.1.1 This estimate is in agreement with an energy saving of 11.8% observed in an iron ore application where VSI’s were introduced as a crushing step preceding the grinding circuit. View Show abstract

Charlar en Línea

Setting up your wash operation for success - Pit Quarry

2021.7.28 Washing and classifying of aggregate can be considered in two parts, depending on the size range of material: 1. Coarse material. Generally above 3/8 in. (and sometimes split at 1/4 in. or #4 mesh). In the washing process, it usually is desired to remove foreign, objectionable material –including fine particles. 2. Fine aggregate.

Charlar en Línea

Simplifying the crushing process - Pit and Quarry

2019.5.10 1. Primary crushing. As the first stage in a crushing circuit, primary crushing reduces material to a size and shape that can be handled by a secondary crusher. Typically, the minimum setting on most primary crushers is about 4 in. to 6 in. Jaw, gyratory and impact crushers are most often appropriate as primary crushers, although there can

Charlar en Línea

Influence of Natural Aggregate Crushing Process on Crushing

2021.7.27 Crushing is one of the most energy-consuming technological processes. The purpose of grinding is to achieve the desired grain size of mineral raw materials. The process of grinding consists of many factors, for example, the size and form of crushed grains, as well as their mutual arrangement inside the crushing machine chamber, the

Charlar en Línea

Crushing in Mineral Processing - 911 Metallurgist

2015.12.26 In mineral processing or metallurgy, the first stage of comminution is crushing. Depending of the type of rock ( geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for

Charlar en Línea

(PDF) Measuring characteristics of aggregate

2006.12.1 Primary and secondary crushing were conducted by a jaw crusher, tertiary crushing in a cone crusher and then the material was milled in a rotor impact mill in closed circuit, with 2.0 mm size ...

Charlar en Línea

MCC Series Cone Crusher Minyu Machinery Corp.

2023.8.7 MCC Cone Crusher. There are generally four types of Standard Cone Crushers: the MCC Standard or Coarse type, the MCF Fine or Medium type, the MCS Short Head type MCSS Super Fine type. All

Charlar en Línea

Barmac® B Series™ impact crushers - Metso

Barmac® crushers are generally used in the last phase of the crushing circuit. Due to their ability to produce precisely shaped end products, these crushers are most popular among aggregates producers, construction industry and recycling applications. In some mining operations, they are utilized in preparing the material feed for grinding.

Charlar en Línea

Downstream Crushing Options for Secondary, Tertiary and

2021.4.12 These types of crushers are usually applied as tertiary or quaternary crushers with less than 2” (75 mm) feed or smaller. Some Vertical Shaft Impactors can be used as secondary crushers with larger feed. Vertical Shaft Impactors are very application-specific. They are sensitive to abrasive materials and can experience very high

Charlar en Línea

Crushing Energy Efficiency - North American Mining Magazine

2021.6.10 According to one estimate, the mining industry consumes 12EJ per year of energy – or 3.5% of total final global energy consumption.1 The energy intensity of mining is also predicted to increase over time as deposits that are lower quality, deeper and more difficult to extract are mined.

Charlar en Línea

Crushers - All crusher types for your reduction needs - Metso

In secondary stages closed circuit calibrates feed to tertiaries. Flow sheet in general. Important, especially in production of very high quality (shape) aggregate is that selective circuits are used, meaning that secondary and tertiary products are not mixed. Fine crushing with impact crushers

Charlar en Línea

Modeling of Crusher Operation - MDPI

2022.1.9 circuits of mineral aggregate production. The circuit that was the object of investigations consisted of two-stage crushing pro-cesses and a series of screening and sieve classification operations. The product from a first stage of crushing in the jaw crusher is downstream classified in a three-decked vibrating screen.

Charlar en Línea

Crushing 101 » Masaba Manufacturing

2019.10.4 8:1 maximum reduction ratio for compression crushing, this is normally used as a primary crusher. Jaws perform well in many materials. Yields low wear cost per ton in hard abrasive deposits, minimal fines but produces little finished (under 1”) product which places more load on the crushers downstream in the circuit.

Charlar en Línea

Geomaterials as construction aggregates: a state-of-the-art

2021.11.22 Construction aggregates derived from primary resources either by crushing of sound rock masses (crushed stone aggregates) or from naturally occurring unbound clastic sediments (natural sand and gravel aggregates) make the most voluminous mineral raw material exploited by humans nowadays (Fookes 1991; Přikryl

Charlar en Línea

>> Next:Chancadora Conica De 2 Piezas Piedra En Venta

- Trituradora Mandíbula Pex250

- teoría de la operación de trituración

- móvil trituradora de mandíbula 50 toneladas por hora

- convinent chancadora de mandíbula móvil

- de alta eficiencia y capacidad de pequeño utilizado chancadoras de roca para la venta

- esquema de trabajo para molinos de martillo

- dubai densidad aparente

- Solucionario Diseño De Elementos De Maquina Robert Mott Pdf

- vendedor de piedra trituradora en Surabaya

- tratamiento de residuos de cianuracion

- ¿que es una celda de contacto en la planta de procesamiento de oro

- vibracion de la pantalla para la piedra

- moinho de barras e bolas

- equipos de la planta de molienda en sudáfrica

- maquila molienda de minerales en guadalajara