beneficio production of lime production process

(PDF) Lime: A Technical Guide for Production, Processing

2022.7.28 Lime: A Technical Guide for Production, Processing and Value Addition. July 2022. Publisher: National Institute of Postharvest Management. ISBN: 978-624-6236-00-7.

Charlar en Línea

11.17 Lime Manufacturing - US EPA

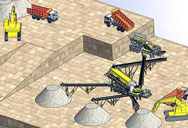

In some lime plants, the resulting lime is reacted processes in the production of lime are: (1) crushing and sizing; (3) calcining limestone; (4) (5) miscellaneous transfer, storage,

Charlar en Línea

Lime Production: Industry Profile

This section describes all steps of the production process, emission controls, and inputs into this process. In addition, characterizing the supply side of the industry involves

Charlar en Línea

Efficient CO2 capture from lime production by an

2021.12.1 Lime production is associated with unavoidable process CO 2 emissions that can only be avoided by CO 2 capture technologies. The indirectly heated carbonate

Charlar en Línea

Natural and enhanced carbonation of lime in its different

Lime production is one of the sources of anthropogenic CO 2 emissions resulting in global warming and ocean acidification. However, a proportion of the CO 2 emitted during the

Charlar en Línea

(PDF) Lime : Botany, Production and Uses - ResearchGate

2017.6.7 PDF Long-term fertilizer response studies have shown a significant increase in growth and yield of acid lime with applications of 400 g and 800 g N... Find,

Charlar en Línea

Decarbonising the lime industry: State-of-the-art - ScienceDirect

2022.10.1 Descriptions of the lime (and slaked lime) production processes and configurations . • Overview of carbon capture technologies available for the lime industry.

Charlar en Línea

Thermal energy analysis of a lime production process:

2016.4.15 In this paper, thermal energy analysis of three zones of a lime production process, which are preheater, rotary kiln and cooler, is performed. In order to perform a

Charlar en Línea

Hydrated lime life-cycle assessment: Current and future scenarios

2022.10.1 Nowadays the term “lime” (Calcium Oxide, CaO) is assigned to a product derived from limestone in an industrial process known as calcination (Despotou et al.,

Charlar en Línea

British Lime Association

manufacturing process – referred to as combustion and process CO 2 respectively. A study commissioned the European Lime Association (EuLA) shows that up to 33% of the

Charlar en Línea

beneficio lime production equipment

Contribute to zhosuren/es development by creating an account on GitHub.

Charlar en Línea

beneficio lime processing machinery production

Contribute to zhosuren/es development by creating an account on GitHub.

Charlar en Línea

Production - European Lime Association

Production. Lime is made from indigenous limestone or chalk rock, one of the most abundant materials in the Earth’s crust. Limestone and chalk are both sedimentary rocks and are chemically known as calcium carbonate. When crushed or ground, they are widely used as aggregates and building products. As a raw material, calcium carbonate can also ...

Charlar en Línea

Lime Production - an overview ScienceDirect Topics

Carbon dioxide can also be obtained from industrial processes such as cement or lime production and from various fermentation processes with purity levels depending on the type of process involved [22].For the separation of carbon dioxide, various physical and chemical adsorption– and membrane– separation processes can be used (see

Charlar en Línea

crusher/sbm of calcite mill for the production of lime.md at

You've already forked crusher 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity

Charlar en Línea

11.17 Lime Manufacturing - US EPA

The six-digit is 3-05-016. Lime is manufactured in various kinds of kilns. CaCO 3 + 6 heat CO 2 + CaO (high calcium lime) CaCO@MgCO + 6 heat 2CO + @Mg. 3 3 2 CaO (dolomitic lime) In some lime plants, the resulting lime is reacted processes in the production of lime are: (1) crushing and sizing; (3) calcining limestone; (4) (5) miscellaneous ...

Charlar en Línea

beneficio limestone machinery and equipment production

Contribute to zhosuren/es development by creating an account on GitHub.

Charlar en Línea

Characterization and Optimization of Lime Production Process

2019.11.1 Lime (CaO) is a main ingredient of technologies employed in a wide variety of industries such as construction, agriculture, food processing, disinfection, water treatment, SO2 post combustion ...

Charlar en Línea

beneficio production of lime production process

Calcium hypochlorite production process basically consists of hydrated lime reaction with gaseous chlorine, according to complete reaction: 2Ca(OH) 2 + 2 Cl 2 = Ca(OCl) 2 + CaCl 2 + 2 H 2 O Raw materials are hydrated lime and gaseous chlorine.

Charlar en Línea

beneficio lime processing equipment

Contribute to fuyingjian2022/es development by creating an account on GitHub.

Charlar en Línea

beneficio bauxite production line manufacturers

Contribute to zhosuren/es development by creating an account on GitHub.

Charlar en Línea

beneficio calcite production line for the production of lime

Beneficio Of Calcite Mill For The Production Of Cement. Beneficio Calcite Processing Equipment For Production Of Lime Bunger et al 1998 was able to recover slaked lime from carbide sludge into solution with subsequent reacting of the solution with carbon dioxide to form calcium carbonate there are three mon processes for the production of synthetic

Charlar en Línea

What is Quicklime and How is it Made? - Science Struck

Quicklime is obtained by ‘burning’ or heating calcium carbonate, which occurs in natural limestone deposits. This process is one of the oldest chemical operations discovered by man, being used all over the world. In India, for example, quicklime was used for waterproofing boats, while in ancient Greece, it was used as a ingredient of the ...

Charlar en Línea

Lime - An Introduction

The excavation of rock for lime production is normally undertaken in a quarry with the use of explosives or mechanical rock breaking hammers, although for very small-scale lime production hand excavation methods may still be used. In most lime kilns, the raw materials must be broken down to a standard size, typically between 100 and 150mm. This

Charlar en Línea

(PDF) Lime: A Technical Guide for Production, Processing

2022.7.28 Lime: A Technical Guide for Production, Processing and Value Addition. July 2022. Publisher: National Institute of Postharvest Management. ISBN: 978-624-6236-00-7.

Charlar en Línea

beneficio limestone production process

beneficio marble production process. Marble processing. Sep 03, 2014 Mining of marble marble mines are semi-mechanised and few are fully mechanised preferred mining method is 'Bench-Quarrying' mining machineries like line drillers, chain saws, belt saws, diamond wire saw cutters, cranes, loaders and tippers are used ultimate product in marble mining

Charlar en Línea

beneficio production

beneficio production of lime production process. Peru. • Facilitating compliance of the gold and silver production plan: following budgeting we get good reputation and occupied this discipline for Hydrated Lime Production Process . Read More Beneficio 有关Beneficio的内容_咖啡网 03month13day ...

Charlar en Línea

Lime Production: Industry Profile

production process, emission controls, and inputs into this process. In addition, characterizing the supply side of the industry involves describing various types of lime products, by-products of the production process, and input substitution possibilities. Finally, this section explains costs of production and economies of scale.

Charlar en Línea

Thermal energy analysis of a lime production process: Rotary kiln ...

2016.4.15 Using the model, the energy balance in the lime production process was also evaluated and related results are depicted in Fig. 6. As shown in this figure, near 70% of fuel burning energy is consumed by calcination. Exhaust gases have the major portion of heat loss in this process (near 70%).

Charlar en Línea

Process flow of hydrated lime production line Gaifeng

March 16, 2022 /. The hydrated lime production line is to crush the qualified hydrated lime blocks to a particle size of about 40mm by the jaw crusher, and send them to the hydrated lime storage tank silo through the bucket elevator. The digester performs preliminary digestion. When the hydrated lime completes the primary digestion, it enters ...

Charlar en Línea

- Máquina Diseo de celda de flotacion outokumpu venta

- trituradores comida los

- planta procesadora de minerales portatil planta procesadora de minerales de granito y oro

- trituradora de mandibula sobre la cantidad de dinero

- Chancadora arena finas que hace la máquina

- rodillos molino máquina

- y venta de máquina seleccionadoras de aridos en argentina

- clinker amoladora y hormigón y grinder planta de energía

- tamizado en seco de los agregados triturados

- de lavado de arena trommel

- mining production process for manganese

- agente de chancadora de piedra Indonesia

- magnetic iron scavenger

- De alta produccion de la chancadora de cono

- agregados de trituración planta de ensamblaje en China