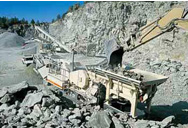

impact crusher rock

Impact Crusher - Eastman Rock Crusher

Impact crusher are named after the method that reducing rock material size, just as its name implies, impact crusher crushes materials by the impact energy. An impact crusher speeds up the feed material to high speed, then throws fast-moving rocks against the crushing chamber walls and each other.

Charlar en Línea

Mobile Impact Crushers, QI Mobile Impact Crusher - SRP

Sandvik's Prisec™ impactor revolutionizes performance and versatility in mobile impact crushing. Available in open or closed circuit, the QI Mobile impact crusher range offers unparalleled levels of control, flexibility and productivity in

Charlar en Línea

IMPACT CRUSHERS - HAZEMAG

HAZEMAG Impactors: The heart of stationary, semi-mobile and mobile crushing plants. Learn more about our Impact Crushers...

Charlar en Línea

New or Used Impact Crusher for sale - Australia - Machines4u

New and Used Impact Crusher insights. There are 15 Impact Crusher for sale in Australia from which to choose. Overall 54% of Impact Crusher buyers enquire on only used listings, 42% on new and 9.32% on both new and used Impact Crusher items.Buyers usually enquire on 1.80 different Impact Crusher classifieds before organising finance.

Charlar en Línea

Mobile Impact Crushers - RUBBLE MASTER

Since 1991, RUBBLE MASTER has brought numerous innovations to the market. We’re crushing screening experts and work closely with contractors and aggregate producers world-wide. RUBBLE MASTER's line of Mobile Impact Crushers recycle concrete and asphalt and crush natural rock with ease. Production capacity range from 90 to 385 TPH.

Charlar en Línea

Impact crushers and impact mills with a horizontal shaft for...

Impact crusher impact mill. Impact crushers and impact mills of type PB and PM are universal and, at the same time, economical solutions. The impact crusher achieves very high crushing ratios in both the first and second stage. This results in a wide range of salable, cubical final products. The impact crusher can be repurposed into an impact ...

Charlar en Línea

Crusher Aggregate Equipment For Sale MachineryTrader

2023.8.29 Rock grinder, stabilizer, stone crusher and asphalt shredder for PTO tractors. ... 2023 EAGLE 1200 CLOSED CIRCUT IMPACT CRUSHER. 540 hours. $1,100,000. Still covered under the manufacturer's warranty. Deister 3 deck screen, tri-axle, CAT Diesel C9.3 tier 4F electric drive, ...

Charlar en Línea

GRB 777 XL Impact Crusher – Armstrong Industries

GRB 777 XL Impact Crusher. $6,500.00. 5 available. Motor. Quantity. Add to Cart. The GRB 777XL has taken a few years to perfect, with endless hours in the workshop. Having 40 years mining experience between my father and I, we know what it takes to build a crusher super tough and reliable. The GRB 777XL Rock Crusher is built for the serious ...

Charlar en Línea

Impact Crusher Working Principle - 911 Metallurgist

2015.6.23 Impact crushing crushing grinding method. Shear crushing is accomplished by breaking along or across lines of cleavage. It is possible, when required, for a crusher to use a combination of two or three of these principles. The selection or sizing of a crusher is much helped by measuring the rock’s hardness during engineering.

Charlar en Línea

Rock Crusher, Crusher Machine, Impact Crusher - Liming Heavy

The rock crusher station can be moved from one place to another place. High efficiency. Works well and easy maintenance. Rock Crusher, Impact Crusher, Crusher machine, Raymond Grinder, Mill Machine are producted by Henan Liming Heavy Industry Science Technology Co.,Ltd., which is one of the biggest manufactories of Mining Equipments in

Charlar en Línea

Rock Crusher Machines Pulverizers Williams Crusher

Contact Williams Crusher. Contact us today to discuss your rock crushing application in detail with one of our experienced sales engineers. Call (314) 621-3348, email us at info@williamscrusher or locate an agent near you. Industry-best rock crushing machines. Reduce particles to your required size.

Charlar en Línea

IMPACT CRUSHERS - HAZEMAG

IMPACTORS FOR SECONDARY AND HARD ROCK CRUSHING . ... whatever the primary crushing application may be: stationary, semi-mobile, mobile. HAZEMAG impact crushers can handle individual lumps of feed material up to 8 tons in weight and 3 m3 (100 cu.ft) ... The compound crusher was developed to avoid the problems and the investment of a

Charlar en Línea

Impact Crushers – Armstrong Industries

IC40 Impact Crusher. $31,460. IC50 Impact Crusher. $37,800. IC55 Impact Crusher. $46,950. We have an extensive range of rock crushers on offer and larger models available upon request. Talk to us today about how we can facilitate a solution for your processing plant requirements.

Charlar en Línea

Types of Rock Crushers Quarry Crushing Equipment Kemper

Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing equipment types, though there can be overlap between primary and secondary crushers as far as suitable types. 2. Secondary Crushing.

Charlar en Línea

Rock Crusher - Eastman Rock Crusher

Stone rock crushers are widely used in many sectors such as mining, smelting, building materials, highways, railways, water conservancy, and chemical industries.At present, there are two types of stone crushing machines commonly used: mobile stone crushers and stationary stone crusher equipment. Stationary crushers include jaw crushers, impact

Charlar en Línea

Rock Crushers, Stone Crushers, Screening and Crushing

We are your long-term partner providing safe and sustainable solutions to optimize productivity through proven expertise in stationary crushing screening. Our Sandvik crushing and screening equipment is engineered for maximum productivity. We offer advanced, proven solutions for any size-reduction and classification challenges.

Charlar en Línea

Jaw Crusher vs. Impact Crusher - What's the difference?

2020.8.21 Aggregate equipment expert Dave Phelan goes in depth about two popular crushing options so you can decide which on is right for you. For more information on ...

Charlar en Línea

RM 120X Mobile Impactor Crush Different RUBBLE MASTER

The RM 120X impactor delivres a high reduction ratio while being easy to maintain. The 4-bar rotor is driven directly through a 400 HP John Deere diesel engine and can be used in primary and secondary crushing applications. The crusher box features a 3-stage single-apron impact wall for fast and easy adjustment of your closed side setting.

Charlar en Línea

RM 100GO! Tracked Impact Crusher RUBBLE MASTER

The RM 100GO! tracked impact crusher weighs 75,000lbs with a top capacity of up to 275 TPH. Skip to content Products Products. Products Mobile Impact ... Secondary crushing after a mobile jaw crusher The RM 100GO! tracked impact crusher processes 8" basalt rock after a jaw crusher producing a 1 1/4"- final product in a closed loop configuration.

Charlar en Línea

Impact Crushers - Cement Crusher Manufacturer - Stedman

An impact crusher is a machine that uses striking as opposed to pressure to reduce the size of a material. Impact crushers are designated as ... crushers, mills, and grinders are used in nearly every mineral and mining industry. Whether you are processing coal, rock, salt, iron ore, wood chips or clay, we have your solution to size reduction ...

Charlar en Línea

Home made Impact mill rock crusher for gold ore. - YouTube

2015.4.27 This video examines the makeup and use of my home made impact mill rock crusher for liberating gold from gold ore. I explain hoe to make a rock crusher or a...

Charlar en Línea

What is an Impact Crusher?

When the rock impacts the anvils or rock shelves, it shatters along natural stress lines, creating a uniform, cubical product. This method is both economical and simple to operate. The VSI has the best rate of production of smaller sizes (- ½”) as it is the only crusher that does not close off the discharge side to make a smaller product.

Charlar en Línea

Impact Crusher - an overview ScienceDirect Topics

The three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 4.4).A jaw crusher consists of two plates, with one oscillating back and forth against the other at a fixed angle (Figure 4.4(a)) and it is the most widely used in primary crushing stages (Behera et al., 2014).

Charlar en Línea

>> Next:Para La Venta Del Alimentador Vibratorio

- gusanos sinfin para molino de nixtamal

- tipos de rectificadora ciliacutendrica

- cuarzo carburo trituradora

- chancadora de impacto de roca para la venta

- dimensiones de trituradora de cono hpc 160

- iron ore fines pelletization machinery and equipment

- trituradoras empresa mineras venta

- maquinas e equipamentos de lavra subterranea

- cone crusher liners business

- fresadora de mármol para la ventamolinos de mármol

- empresas chancadoras de minerales

- clasificador en espiral para el mineral de hierro de la mina

- proveedores planta trituradora en arabia saudí

- difference entre triturador y molino

- mandibula formula capacidad de la trituradora