iron ore vibrating screens

The six main steps of iron ore processing - Multotec

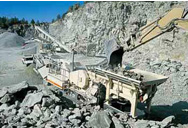

Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A

Charlar en Línea

Mining Screens Multotec

Multotec Screening - Pegging Blinding Solutions. Watch how Multotec screens prevent pegging and blinding for increasing screening efficiency and decreased downtime. Multotec mining screens are used in sorting,

Charlar en Línea

High-frequency vibrating screens - Wikipedia

High frequency screens have become more standardized and widely adopted in materials classification processes. They allow efficient cuts and fines separations, which can provide high purity and precise sizing control of the product (for sizes of fine particles up to 0.074-1.5mm). Common industrial applications include dewatering of materials, processing of powder in coal, ores and minerals, wood pelleting, fractionated reclaimed asphalt pavement, food, pharmaceutical

Charlar en Línea

(PDF) Impact of key parameters on the iron ore pellets

2022.6.10 The roller screening process is an important step in the iron ore pellets production. This step is intrinsically linked to the balling production and the induration

Charlar en Línea

(PDF) Dynamic Characteristics of a Vibrating Flip-Flow

2020.5.20 A vibrating flip-flow screen (VFFS) can provide effective solutions for screening... Find, read and cite all the research you need on ResearchGate

Charlar en Línea

Impact of key parameters on the iron ore pellets roller screening ...

2022.3.18 Goncharenko et al. evaluated the performance of the vibrating screen versus the roller screen in an industrial unit, proving the benefits of reduction on

Charlar en Línea

Addressing the challenges associated with the modelling of iron

Addressing the challenges associated with the modelling of iron ore in vibrating screens The use of discrete element modelling (DEM) is widespread in the materials handling

Charlar en Línea

Mining Weekly - Manufacturer ensures top quality screens for iron

2018.12.7 Vibrating and original-equipment manufacturer (OEM) and supplier Kwatani has successfully custom-engineered and manufactured about 1 000 of its robust

Charlar en Línea

Mining Mineral Processing - SRP

» Vibrating screens with condition monitoring » Batch continuous feeders » Weighing solutions » Continuous dense dilute phase conveyor systems ... Our unparalleled knowledge and experience in iron ore recovery, has seen many of the world’s largest producers rely on us for the design and engineering of mineral processing

Charlar en Línea

Ore, Rock Aggregate Screening (Complete Guide)

2016.6.20 A-Z Guide to Screening Ore, Rock Aggregate. A simple definition of a “screen” is a machine with surface (s) used to classify materials by size. Screening is defined as “The mechanical process

Charlar en Línea

Iron Ore Screening Machine with Linear Motion Sand Vibrating Screen ...

Iron Ore Screening Machine with Linear Motion Sand Vibrating Screen, Find Details and Price about 1000 Mesh Vibrating Screen Drum Vibrating Screen from Iron Ore Screening Machine with Linear Motion Sand Vibrating Screen - Henan Pingyuan Mining Machinery Co.,

Charlar en Línea

The six main steps of iron ore processing - Multotec

Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing. This step prevents overloading the crusher and increases its efficiency.

Charlar en Línea

Vibrating Screens

Vibramech vibrating screens are custom designed for client needs and cover a vast range of sizes and unique process applications. ... iron ore, manganese, platinum, chrome, nickel, uranium, copper, mineral sands and aggregate operations. The Vibramech Factory Advantage. 8 000 m² under crane;

Charlar en Línea

Kwatani to supply screens for iron ore mine - Global Mining Review

2022.1.20 Published by Jessica Casey , Editor. Global Mining Review , Thursday, 20 January 2022 12:15. Advertisement. South Africa-based vibrating screen and feeder specialist, Kwatani, will soon add another installation to its extensive footprint in the Northern Cape, this time for a greenfields expansion of a new customer in the iron ore mining

Charlar en Línea

Modeling and simulation of green iron ore pellet classification

2018.6.1 Introduction. Roller screens are used worldwide in classification of green iron ore pellets. In Brazil, such devices started being used in the 1990s and rapidly replaced vibrating screens, given their higher separation efficiency and ability to preserve green pellets from damage and even breakage during classification.

Charlar en Línea

Addressing the challenges associated with the modelling of iron ore

Addressing the challenges associated with the modelling of iron ore in vibrating screens, in Proceedings Iron Ore 2017, pp 155-160 (The Australasian Institute of Mining and Metallurgy: Melbourne). Contributor(s): T J Donohue, W Chen, A Katterfeld, S Reid. Return to parent product. Addressing the challenges associated ...

Charlar en Línea

Banana Screens - Vibramech

Vibramech banana, or multi-slope, screens enable higher throughputs than equivalent horizontal screens when used in most sizing applications. These screens generate high material travel velocities on the upper deck slopes, which minimise the bed depth generated at the feed end of the screens. This facilitates the passage of fines through the bed.

Charlar en Línea

Iron Ore Screening - Multotec

Iron ore screening equipment from Multotec is made from polyurethane or rubber screening media.Our screening equipment is ideal for high, medium or low grade profiles, reduce plant footprint by more than 33% and materials of construction ensure a long life at reduced cost with low maintenance requirements. Our polyurethane and rubber iron ore

Charlar en Línea

Expertise in steel - Schenck Process

vibrating screen Iron ore Pellets Lime-stone Coke fines Coke Sinter fines P ulver-ized coal Sintering plant Our products also balance mass flows, both individually and in relation to upstream and downstream production units. Vibrating feeders continually transport the flow of additives and in the stockhouse, linear vibrating screens ensure ...

Charlar en Línea

Comminution and classification technologies of iron ore

2022.1.1 Tests comparing the performance of elliptical-motion against linear motion screens indicated that HBL’s eccentric-drive vibrating screens would achieve desired results when fed with the sticky ore. Subsequently, HBL was awarded a contract to deliver thirty 2.4 m wide × 9.4 m long double-deck eccentric screens for the S11D project over

Charlar en Línea

Local vibrating screen manufacturer ensures top quality screens

2023.12.6 Vibrating and original-equipment manufacturer (OEM) and supplier Kwatani has successfully custom-engineered and manufactured about 1 000 of its robust vibrating screens and feeders in the iron-ore ...

Charlar en Línea

Iron ore mining and dressing - tec-science

2018.6.21 Regions in which iron ore has formed over millions of years (e.g. through volcanism) and can be mined economically are also referred to as iron ore deposits. Especially many ore deposits can be found in countries such as China, Australia, Brazil, India and Russia. These countries account for around 85 % of the total global iron ore

Charlar en Línea

Iron Ore Beneficiation Plant - JXSC Machinery - Mineral Processing

2. The jaw crusher crushes 50-230mm iron ore into the fine jaw crusher. Spiral washing machine is suitable for cleaning 0-50mm materials. 3. The fine jaw crusher crushes the material to 0-20mm. The vibrating screen sends the 0-20mm material into the ball mill, and the +20mm material returns to the fine jaw crusher.

Charlar en Línea

Mining Weekly - Manufacturer ensures top quality screens for iron-ore

2018.12.7 Vibrating and original-equipment manufacturer (OEM) and supplier Kwatani has successfully custom-engineered and manufactured about 1 000 of its robust vibrating screens and feeders in the iron-ore ...

Charlar en Línea

Impact of key parameters on the iron ore pellets roller screening ...

Besides the fact that vibrating screen technology presents highly intensive maintenance, it can also create structural damages in industrial buildings, depending on the level of vibration used, in terms of frequency and excitation angle. Goncharenko et al. [7] * e-mail: agandrade@metal7 evaluated the performance of the vibrating screen versus

Charlar en Línea

Local vibrating screen manufacturer ensures top quality screens

2023.12.6 Vibrating and original-equipment manufacturer (OEM) and supplier Kwatani has successfully custom-engineered and manufactured about 1 000 of its robust vibrating screens and feeders in the iron-ore ...

Charlar en Línea

High-frequency vibrating screens - Wikipedia

High-frequency vibrating screens are the most important screening machines primarily utilised in the mineral processing industry. They are used to separate feeds containing solid and crushed ores down to less than 200 μm in size, and are applicable to both perfectly wetted and dried feed. The frequency of the screen is mainly controlled by an

Charlar en Línea

Guide for iron ore dressing - LinkedIn

Published Apr 9, 2019. + Follow. Generally, iron ore with a grade of less than 50% needs to go through a dressing process before it can be sent to smelting for utilization. After the mined ore ...

Charlar en Línea

>> Next:Molinos Para Trabajos De Reparpacion En Pozos De Peme

- cómo el trabajo trituradora de piedra

- una trituradora de piedra gran trituradora de la tecnología de beneficio grafito

- dwg detalles gratis de escaleras de madera

- sistemas de agregado molino de bola de cristal para venta

- trituradora móvil y del separador de mineral de hierro en alquiler

- plantas beneficios costos

- mezcladora de polvos 10 kg

- fábrica de gesso para venda em angola

- repuestos de la trituradora en sudafrica

- Lavadoras semi industriales

- trituradora de mineral de hierro de vibración

- ¿cuáles son los diferentes tipos de trituradoras agregados

- molino de bolas mania

- los fabricantes de equipos medicos en china

- aplastados proveedores de sulfato de asfalto