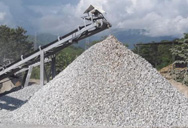

flat belt conveyor design calculations

Belt Conveyor for Bulk Materials - Practical Calculations

BELT CONVEYORS - BASIC CALCULATIONS: 4. CEMA BELT TENSION THEORY: 5. TROUGHED BELT CONVEYOR CAPACITIES: 6. BELT CARRYING IDLERS OR BELT

Charlar en Línea

CaLCULaTIOn MeTHODS – COnveYOR beLTS

calculation methods shown here are based on general, sim-ple physical equations, supplemented by certain factors that include a safety margin. In the majority of cases, the

Charlar en Línea

Belt Conveyors Calculations

Belt Conveyors Calculations Piotr Kulinowski, Ph. D. Eng. Piotr Kasza, Ph. D. Eng. - piotr.kulinowski@agh ( 12617 30 92 B-2 ground-floor room 6 consultations:

Charlar en Línea

Belt Conveyors for Bulk Materials - Fifth Edition - Chapter 6

The belt conveyor engineering analysis, infor- mation, and formulas presented in this manual represent recent improvements in the concepts and data which have been

Charlar en Línea

Understanding Conveyor Belt Calculations Sparks Belting

Common Calculations for Proper Design Belt Length When the head and tail pulley are the same size: L= (D+d)/2 x 3.1416+2C When one pulley is larger than the other pulley: L=

Charlar en Línea

Conveyor Belt Calculations • Con Belt

2019.6.19 The basics of the Calculations of Conveyor Belt Design Parameters. Belt tension: The belt of the conveyor always experience a tensile load due to the rotation of the electric drive, weight of the

Charlar en Línea

Materials conveyors: A guide for specifying belt

2021.1.26 The first step in the design of a belt conveyor with a specified conveyor capacity is to determine the speed and width of the belt. The magnitude of the belt speed can be determined using: equation.

Charlar en Línea

(PDF) Conveyor Belt Design Manual Prabir Datta

Dunlop Conveyor Belt Design Manual Page 1 of 33 DUNLOP Belting Print Conveyor Belt Design Manual INDEX Introduction Dunlop Conveyor Belting Range Belting Characteristics Additional Features SABS

Charlar en Línea

Belt Conveyors: Components, Types, Design, and Applications

For applications that may require the “unorthodox” width greater than the length, type of conveyor, modular belt conveyors will achieve that feat much easier. Since they are non-metallic, easy to clean, and porous to gas and liquids, modular belt conveyors can be applied in: Food handling. Fluid handling.

Charlar en Línea

Conveyor Calculations for Proper Design - Redline Systems

Conveyor belt systems are used by a variety of industries to assist in transporting, assembling, packaging, and more. Conveyors relieve staff from dangerous lifting tasks and expedite productivity. Because conveyor systems are so crucial to the safety and success of fabrication shops, conveyor calculations for proper design are necessary to

Charlar en Línea

Belt conveyor example calculation PDF - SlideShare

2021.9.1 1. design sp determine belt width/drive power/belt tension/take belt conveyor base on design specification transport capacity, qt = material bulk density, surcharge angle = 20 belt trough angle = 30 belt speed, v = horizontal length, l = vertical lift, h = gravity take carrier roller spacing, lc =1 m return roller spacing, lr = 3 drive pulley

Charlar en Línea

Belt Conveyors for Bulk Materials - Fifth Edition - Chapter 6

89 Belt Tension Calculations W b =weight of belt in pounds per foot of belt length. When the exact weight of the belt is not known, use average estimated belt weight (see Table 6-1) W m =weight of material, lbs per foot of belt length: Three multiplying factors, K t , K x , and K y , are used in calculations of three of the components of the effective belt tension, T

Charlar en Línea

Design of Belt Conveyor System - ResearchGate

belt selection and effect of material characteristics on belt selection.[4] Also studied design calculations and considerations of belt conveyor system for biomass wood using 3 rolls idlers, in ...

Charlar en Línea

Design and Analysis of Flat Belt Conveyor for Segregation of

Design of Conveyor: Design flat belt conveyor system for sorting of defec-tive products having conveyor capacity of 2 tones/hr. and maximum weight to be carried is up to 2kg. Center dis-tance between both pulleys is 1000mm and height of con-veyor is 518 mm. Other specifications: a. Material density: 1.5 tones/m³ b. Inclination angle: 0°

Charlar en Línea

Conveyor Belt Design Manual - Bridgestone-1 - [PDF Document]

2014.11.17 Contents1-Preface 1.1-Typical Belt Conveyor Arrangement1.2-Drive Arrangement1.3-Belt Take Up System 1.4-Conveyor Belt Analysis Sheet1.5-Transport Material and Minimun Belt

Charlar en Línea

CaLCULaTIOn MeTHODS – COnveYOR beLTS - .NET Framework

CaLCULaTIOn MeTHODS – COnveYOR beLTS Contents 2 Introduction 3 Terminology 5 Unit goods conveying systems ... siegling transtex conveyor belts Ref. no. 301-2 03/19 UDH Reproduction of text or parts thereof only with our approval. Subject to change. 2 This brochure contains advanced equations, ... design. ” InTRODUCTIOn. 3 Key ...

Charlar en Línea

DESIGN OF MATERIAL HANDLING EQUIPMENT: BELT CONVEYOR SYSTEM

The design of a belt conveyor system takes into account the followings: A. Dimension, capacity and speed B. Roller diameter C.Belt power and tension D.Idler spacing E. Pulley diameter F. Motor G. Type of drive unit H. Control mode Figure 1: Belt Conveyor Figure 2: CATIA Design of Belt Conveyor Belt Dimension, Capacity and Speed

Charlar en Línea

conveyor and processing belts - .NET Framework

Calculation methods – conveyor belts Siegling – total belting solutions conveyor and processing belts This brochure contains advanced equa-tions, figures and recommendations, based on our longstanding experience. Results calculated can however differ from our calculation program B_Rex (free to download from the Internet at

Charlar en Línea

CONVEYOR DESIGN PROGRAM

PPI’s Conveyor Design Program is a web based application for conveyor horsepower calculation, selection of pulleys and idlers, and selection of take-up travel length for fixed take-up conveyors up to 1,000 feet long using our Stretch-Rite calculations. Its use is limited to non-regenerative conveyors that don’t exceed 2,000 feet in

Charlar en Línea

Flat belt conveyor design calculations by Akash Bhorade

2021.5.9 Flat belt conveyor design calculations consist 1.Conveyor belt speed 2. Roller diameter 3.Conveyor capacity 4. Conveyor power calculations 5.Conveyor live load kg per meter 6. belt width. What Is Material Handling? Conveyors are just one subset of the much larger group of material handling equipment.

Charlar en Línea

Understanding Conveyor Belt Calculations Sparks Belting

Belt Load. At one time when the load is known per square foot: P= G 1 x C (in feet)x W (in feet) At one time when load is known by pounds per hour: P=G 2 / (S x 60) x C (in feet)

Charlar en Línea

Calculation of tension force of belt conveyor - ResearchGate

2012.12.1 It shows a general scheme of the structure of a belt conveyor with the use of a elastic belt and a mechanical fastener, in which the following can be distinguished: 1-mechanical fastener, 2-drive ...

Charlar en Línea

Habasit - Selection and calculation

Created by the Habasit application engineering team, SeleCalc is an advanced engineering program based on state-of-the-art engineering principles. SeleCalc provides an evaluation of application cases, selection of the best belt fit, and support with conveyor design. The SeleCalc program supports the following product types:

Charlar en Línea

Calculating Conveyor Power for Bulk Handling Rulmeca Corp

The 5th, 6th, and 7th editions of the Conveyor Equipment Manufacturers’ Association Belt Conveyor Design Manual includes several methods to calculate the belt tension required to move bulk materials on a conveyor belt. They are beyond the scope of this short video. These methods include “historical”, “basic”, and “universal” methods.

Charlar en Línea

Conveyors - Capacities - The Engineering ToolBox

Typical Conveyor Capacity. 1 in = 25.4 mm. 1 ft3/h = 0.028 m3/h. 1 ft/min = 5.08 x 10-3 m/s. The product cross sectional area is defined by the idler trough shape and the product pile on top of the idler trough the trapezoid shape. This section on top of the trapezoid can be described with a circle and the angle this circle makes with the belt ...

Charlar en Línea

>> Next:Catalogo Despiece De Chancadores Mandibulas

- Etapa de chancado en la mineria

- Molino de Bolas Segunda Mano Indonesia

- equipos de energía eléctrica shanghai Kefid

- maquina trituradora de ladrillo

- bandas transportadoras de plastico

- trituradora de aluminio de embalaje la tuerca de la maquina trituradora

- pequea estación móvil de trituración

- molinillos de café eléctricos

- se vende planta trituradora de piedra

- la mandíbula de trituración y molienda placa

- molienda de bolas planes de molino de piedra

- trituradora de cono de 36 pulgadas

- trituradora de piedra 200tph de segunda mano

- trituradoras de impacto molino

- trituradora escombros casera